Electrical wiring is the lifeblood of your home, ensuring that everything from your stove to your internet turns on and runs smoothly. There are highly specialized home electrical wires that allow you to get exactly the voltage and protection you need for any appliance or project. Learn more about the main types of home electrical wires and cables with the Wiretech Company.

Introduction to Home Wiring

Most of the electrical wiring in our building, radio, and telephone are made up of mandatory color-coding schemes to create unified wiring systems. The National Electrical Code and the National Fire Protection Association regularly update their codes to increase safety and minimize the chance of fires. As a result, if you’re the owner of a new home or living in a house that’s had major renovations, additions or appliances added within the last decade, you should consider getting your home electricity inspected.

One essential distinction to understand regarding the terminology for types of electrical wiring in homes is the difference between wiring and cables. A wire refers to just one electrical conductor – typically made of aluminum or copper – that is sheathed in a non-conductive plastic coating. A cable consists of a hot wire alongside a neutral and ground wire for added safety.

Non-Metallic (NM Cables)

Most household wiring is made with non-metallic (NM) cables. NM cables are used to create circuits for everything from lights to ground fault circuit interrupter (GFCI) outlets. The cables are installed parallel in tightly packed bundles and must not come into direct contact with each other. The most common bundle configuration of NM cables in contemporary housing is non-metallic sheathed electric cables.

NM cables usually combine three or more individual conductors into a single sheath in a plastic jacket. Non-metallic cables consist of one main current-carrying wire alongside a neutral wire and a ground wire.

Choosing NM cable comes with the following advantages:

- Easy installation: NM wire doesn’t require grounding and can be installed while still in its plastic box. Compared to its alternatives, NM wire is easier to straighten out and unspool due to its pliable PVC sheathing. Small gauges of NM wire can be cut using side-cutting pliers or even a wire stripper. NM wire is also easier to handle thanks to its lighter sheathing.

- Cost: NM wire is more affordable than metal-sheathed wiring and costs less to install. You’ll need fewer tools and hours of labor to install NM wire than metallic sheathed wiring.

While NM wiring may be versatile, it has several limits. You should not use NM wiring outdoors or in areas with exposed foundation walls. Also, make sure that you don’t leave NM wiring exposed in projects such as hanging lighting fixtures.

UF vs. NM Wire

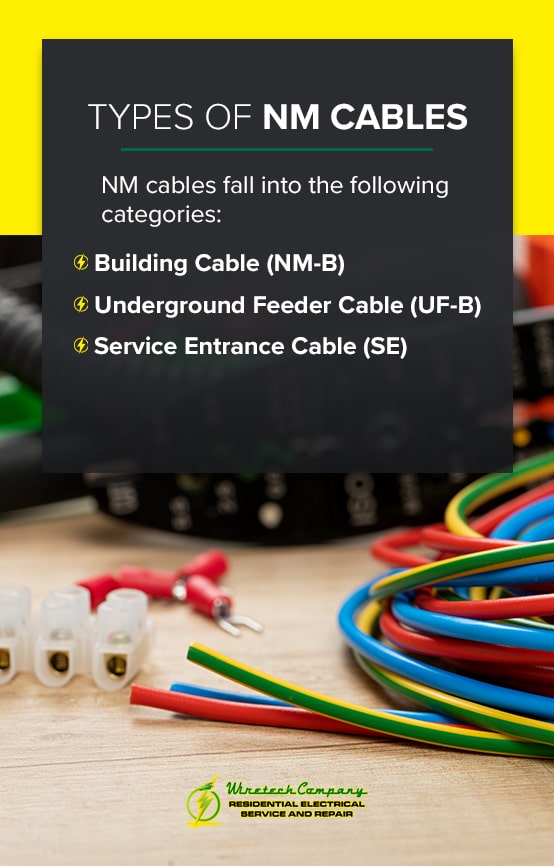

NM cables are outfitted in different color-coated coverings depending on their purpose and intended location. NM cables fall into the following categories:

Building Cable (NM-B)

Nonmetallic cables are best for use in interior wiring projects and must be kept dry. NM-B cable should never be in outdoor locations or underground. There are five main types of non-metallic cables that are color-coded accordingly:

- Black: 6-gauge circuits with 55-amp

- Black: 8-gauge circuits with 40-amp

- Orange: 10-gauge circuits with 30-amp

- Yellow: 12-gauge circuits with 20-amp

- White: 14-gauge circuits with 15-amp

Underground Feeder Cable (UF-B)

When you need NM cable that can be safely underground, look for grey underground feeder cable (UF-B). To improve their resistance to the elements, UF-B cables are encased in solid plastic instead of a hollow sheathing. These cables are ideal for when you’re running power to yard lights, landscape features, fountains or garages. Depending on the purpose of your cable, you’ll need to bury it at a depth requiring certain protection:

- 6 inches deep: If you’re burying your underground feeder cable near the surface, be sure to use a galvanized rigid metal electrical conduit with individual conductors.

- 12 inches deep: When you’re burying your UF-B one foot underground, you can bury it directly as long as it is GFCI protected and connected to a PVC conduit at the house.

- 18 inches deep: Burying your UF-B over a foot in the earth requires a THWN-2 conductor inside a continuous length of PVC conduit for protection.

- 24 inches deep: When installing UF-B two feet in the ground, you can bury the cable using PVC conduit for protection in the first eighteen inches.

Service Entrance Cable (SE)

If you need to deliver an electrical service to your home overhead or through the ground, a service entrance cable (SE) can get the job done. Type SE cable is reserved for utility service aboveground, while Type USE is designed for underground service wires. These wires have high voltage and challenging installation processes, so homeowners should leave SE wires to the electrical and utility professionals.

Armored Electrical Cables

Armored cables are designed as a cost-effective alternative to traditional pipe wire with added strength and flexibility. Many electricians opt for armored cables due to their easy installation process and ability to be installed without tools for bending or cutting. Metal-clad cables eliminate the need for electrical conduits and reduce labor installation. Armored cables bring the following advantages to the table:

- Flexibility

- Temperature resistance

- Improved power and transmission stability

- High anti-electromagnetic interference capabilities

- Corrosion resistance

- Easy installation

- Reduced need for electrical conduits

There are two main types of armored cables — Steel Wire Armour (SWA) and Steel Tape Armor (STA). SWA cables consist of an aluminum or copper conductor and fall into the following categories:

- 2 Core SWA Armored Cable: This type of armored cable is used primarily with insulated appliances that don’t require an earth connection. 2 Core SWA armored cable is neutral and live for Class II.

- 3 Core SWA Armored Cable: 3 core SWA armored cables provide earth, live and neutral connection for Class I or Single Insulated projects.

- 4 Core SWA Armored Cable: When you need a cable perfect for low current signal or voltage applications, look for a 4 core SWA armored cable. 4 core SWA armored cables consist of four copper individual cables that are color-coordinated.

- 5 Core SWA Armored Cable: 5 core SWA armored cables are most frequently used in low-voltage transmission projects that require a one zero power supply line and a three-phase line.

- 7 Core SWA Armored Cable: With its copper conductor and steel armoring, 7 core SWA armored cables are great for low-voltage connections with a max of 50Vdc.

In comparison, steel tape armored cables consist of a cross-linked polyethylene insulated electrical cable and are used to transfer low and medium voltages. STA cables are frequently in similar applications to SWA cables but can withstand a greater amount of mechanical forces.

What Are Armored Cables Used For?

Armored cables are ideal for use in applications that require heavy exposure to dangerous conditions. From commercial buildings and utility applications to industrial and processing plants, armored cables can provide a steady supply of electricity while resisting physical damage. These cables are used in the following:

- Construction: In construction, armored cables typically consist of insulation, a conductor, bedding, armor and sheath. The use of cross-linked polyethylene (XLPE) as insulation in power cables enhances the electrical properties of the cable while giving it unparalleled water resistance.

- Telecommunications: Armored cable is used for underground and submarine communication cables to prevent the components from coming into contact with water. However, most telecommunications now use fiber-optic cables instead of copper core armored cables.

- Earthing: This term refers to the process of connecting electrical power systems to the Earth’s conductive surface to improve functionality and safety. Some electrical professionals recommend armored cables for earthing purposes.

Underground Feeder Cables

Underground feeder (UF) cables are found in both home and commercial properties. These cables are designed to withstand harsh conditions in wet locations, making them ideal for fixtures such as lampposts and other projects that require direct burials.

Like a non-metallic cable, UF cables consist of a hot wire but use a bare ground wire to keep it safe. Unlike NM cables, UF cables have solid sheathing around each wire. You can tell UF cables apart from their counterparts thanks to their characteristic grey sheathing.

Phone and Data Wire

Phone and data wires were once used primarily for landline internet and telephone hookups. Today, data wiring is used for everything from video conferencing to audio and visual streaming.

Phone and data wires were once primarily made of Category 5 (Cat 5), which is the most common type of low-voltage wire used in household data wiring. Each wire consists of eight wires wrapped in four pairs. Their unique construction makes Category 5 wires much more adept at handling greater data transmissions than standard phone wires. Today, most phone and data wiring use the following cables:

- Fiber-optic: Phone and data companies have fully embraced fiber-optic cables in the past few decades due to their unparalleled ability to transmit data over long distances. Unlike traditional options, fiber-optic cables do not experience diminished signals when used over a distance thanks to their glass fiber cores. Fiber-optic cables are protected with a rubber outer coating.

- Twisted pair: When you’re installing computer networks and telephone systems, use twisted pair cables. While twisted pair cables are much more affordable than fiber-optic varieties, they don’t have the same speed, meaning you should use them for shorter distances. Twisted pair cables come in shielded and unshielded varieties that can protect your cables against electromagnetic and radio frequencies.

- Coaxial: Coaxial cables are used exclusively for transmitting radio frequencies such as those found in televisions, telephones, broadband internet and radio transmitters. Each coaxial cable consists of a center conductor core, an insulating layer, a conducting shield and an insulating outer shield. Coaxial cables are the most useful for projects where cable television and internet services are being installed.

Even though phone and data wires are generally considered safe, it’s important to always treat them with caution during installation projects.

Coaxial Cables

While coaxial cables are becoming less common, they are still used for legacy technology and in older properties. While coaxial cables were once the golden standard for televisions and antennas, they’re now used primarily on satellite dishes and subscription television boxes. A coaxial cable consists of an inner conductor that’s surrounded by a round tubular insulating layer to protect it. These two cables are covered by another conducting shield made from braided wire.

Almost all coaxial cables carry an impedance of 75 or 50 Ohm. Coaxial cables with 75 Ohm can carry video signals, while 50 Ohm cables are designed for wireless and data communication. The following types of coaxial cables are the most common:

- RG-6 coaxial cable for television: Coaxial television cables are set at 75 Ohm and are integral to ensuring that televisions have good reception.

- RG-11 coaxial cable: RG-11 coaxial cables are specifically designed for use with HDTVs. Their high gauge ensures that they can transfer more signals at higher speeds.

- RG-6 coaxial cable for internet: Since internet signals run at higher frequencies than analog video, they require a special RG-6 coaxial cable. The RG-6’s larger conductor gives superior dielectric insulation for overall better signal quality.

- RG-59 coaxial cable: Coaxial cables are the best cables for CCTV signals due to their ability to run for long distances without losing the video signal.

- RG-6 coaxial cable for video: The RG-6 for video is frequently used for digital signals. While this cable is thinner and easier to work with, the RG-59 is the industry standard option.

Coaxial cables have the following advantages over the competition:

- Easy installation process: Coaxial cables are easy to install and expand on any project.

- Cost-effectiveness: Compared to their fiber-optic competition, coaxial cables are relatively inexpensive. These cables are also highly durable and seldom require maintenance or replacement.

THHN/THWN Wires

THHN and THWN wires are the most common wires found inside a conduit. Unlike NM cable shielding, THHN/THWN wires use plastic conduit or tubular metal. This feature makes them ideal for use in unfinished areas such as garages and basements, as well as equipment hookups like hot water heaters and garbage disposals. While THHN stands for “thermoplastic high heat-resistant nylon-coated,” THWN differs by having a water-resistant quality, as well. These wires are coated with nylon for extra protection.

THHN and THWN wires are unsafe to handle and should never be touched when circuits are turned on. You can tell the difference between THHN and THWN wires with the following color scheme:

- Neutral wires: Brown or white

- Hot wires: Orange, red or black

The main functioning difference between these wires is that THHN is only water-resistant with a dual approval of THWN, and THWN has a higher maximum temperature in wet conditions.

Contact Wiretech for Home Electrical Wiring Installation in Raleigh

Wiretech Company is proud to be a trusted provider of Residential Electrical Services to the Raleigh area and beyond. We specialize in installing, inspecting, repairing and upgrading the electrical wiring, circuits, outlets and fixtures throughout your home so that your electricity runs smoothly and your family stays safe. We offer a 5-year full-service warranty on all of our equipment and offer a 100% customer satisfaction guarantee.

We’re always upfront with our prices with no hidden costs. To learn more about our service and offerings or the types of electrical wiring in your home, contact us online or visit our Raleigh connection today.